The product enters a sampling tray or chamber where the moisture measurement is taken. A digital output of the Processor Unit is used to control the fill and purge method of sampling. Sampling Sensors can be found in production processes where a small sample is taken from a large flow of product or where it is not possible to maintain a reasonably constant flow of product over the sensor.

Moisture Sampling Sensors: Common types of Sampling Sensors include a Piston Purge, Air Purge, and Down Chute Application Interface that uses different techniques of sampling the product.

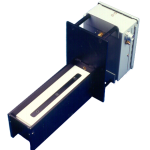

Piston Purge Moisture Sensor: The Piston Purge Sampling Series utilizes a hydraulic piston mechanism allowing product to enter the sampling chamber for measurement and purging the chamber after the measurement has been taken. The piston-purged sensor resembles a large syringe. A 150mm diameter fiberglass lined chamber forms a cylindrical sensor. A piston retracts allowing the chamber to fill with product. After measurement, the piston advances, returning the material to the product flow.

Air Purge Moisture Sensor: Likewise, the Air Purge Sampling Series uses a similar fill and purge technique using compressed air in lieu of the hydraulic piston mechanism. Many low-density powdered products are conveyed by blowing or sucking through pipelines. This is known as pneumatic conveying and is widely used in the grain processing industry. By simply cutting a hole in the pipeline, the sensor may be saddle mounted with clamps. The angled sensor captures a small proportion of product. When full, a measurement is taken and a solenoid valve is activated to evacuate the sample chamber with compressed air.

Down Chute Moisture Sensor: The Down Chute Sampling Series allows product to fall into the sampling tray and purges the product with a blast of compressed air. The down-chute sensor is a sealed planar sensor with low side walls forming a sensor tray. The tray is inserted into a vertical gravity-fed chute through a rectangular hole. The vertical flange bolts to the chute wall. Product free falling down the chute fills the tray to overflowing. A measurement is taken and then an air-purge nozzle empties the tray.

Time Sampling Moisture Sensor: The Sampling Series, when used in timed sampling mode, provides a digital output to activate a solenoid valve. This mode provides two programmable functions, fill time and purge time. Fill time is a do-nothing period of time to allow the sampling chamber to fill with product. Fill time is followed by a fixed 1-second measurement time which is then followed by the purge time during which the digital output is set high for the programmed duration. The instrument display is updated following the measurement interval and held until the next measurement.

Gallery:

No video is available for this product