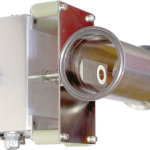

The product flows through the pipeline where the moisture measurement is taken. The Application Interface is made up of a pipe with attached sensor electronics that is integrated into the pipeline framework of the production process. An optional heater jacket ensures that the product does not solidify. Typically used with production processes manufacturing fluids, pastes, and confectionery applications. Applications include caramel, molasses, molten candy and fudges.

Common Pipe Line Sensors: The most common pipeline sensor is 50mm diameter (other sizes available) with a slight flat side incorporating a button sensor (bottom right image). This type of sensor is good as long as product flows uniformly throughout the section of pipe.

Product Temperature: If side-wall build-up occurs it is a problem. Most confectionary products flow through the pipes at very elevated temperatures, typically 120°C – 140°C. At the beginning of a production run, the pipe may be cold and a layer of product immediately forms on the inside of the pipe. This layer may never melt off throughout an 8 hour production run. Running hot water through the system prior to production is helpful. Some systems use steam jacketed piping. If this is not possible, a coaxial sensor should be considered (bottom left image).

Coaxial Pipeline Sensors: The coaxial sensor’s electric field is radial from the center electrode to the outer pipe wall. Thus the electric field must penetrate moving product, even if a build-up occurs.The main disadvantage of a coaxial sensor is that it normally needs removing from the process for cleaning and some users do not like having an obstruction in the pipeline.

Pipeline Heater Jacket: A heater jacket option surrounding the pipe is available upon request. In this case the pipe is electrically heated to just below the normal operating temperature to ensure product does not tend to solidify.

Gallery:

No video is available for this product