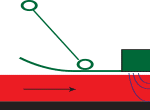

The product passes underneath the sensor where the moisture measurement is taken. The sled hangs from hinged arms allowing it to maintain a parallel position to the conveyor and to level the product for consistent measurement. Maintaining a depth of product greater than the penetration of the RF field is particularly important for the application. Typically used on conveyors (sloping/horizontal).

Planar Moisture Sensors: Planar sensors may be used to measure powdered products on belt conveyors. A scraper is located above the conveyor to level the product. A planar sensor is attached to the down-stream side of the scraper approximately 6mm above the leveled product. In some cases the scraper may be adjusted up or down to regulate flow. In this case, the sensor moves with the scraper, always maintaining a 6mm product/sensor gap.

Sled Sensors: Often, the nature of the product does not allow easy leveling. In these cases, sometimes a sled sensor may ride on the product, essentially maintaining a constant sensor/product gap. The sled hangs from dual arms on each side forming a parallelogram action to maintain the sensor parallel to the conveyor.

Depth of Penetration: Using the scraper method or the sled, it is important to maintain a depth of product greater than the penetration of the RF field, particularly for metal conveyors.

Skid Plate Sensor: Other varieties of Sled Series include the Skid Plate Application Interface that has a smooth abrasion proof surface designed to have a gentle impact on sensitive products. A Skid Plate Sensor is typically used on board lines where the board is not self-supporting and the sensor must be in contact. The illustrated Skid Plate has a high-alumina contact window flush mounted in a hard anodized aluminum plate offering a perfectly smooth surface so not to mark board it contacts.

Gallery:

No video is available for this product