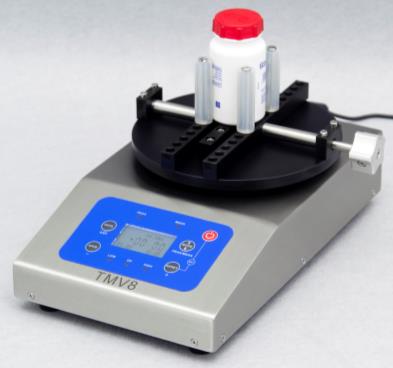

A bottle cap torque tester is a specialized instrument designed for the measurement and evaluation of the torque applied to bottle caps or closures. It is commonly used in industries such as beverage manufacturing, pharmaceuticals, food processing, and cosmetics, where proper sealing and tightness of bottle caps are critical for product quality and safety. Here are some key features and applications of bottle cap torque testers:

- Torque Measurement: The primary function of a bottle cap torque tester is to measure the torque required to open or close a bottle cap. It quantifies the rotational force applied to the cap in units like pound-inches (lb-in), pound-feet (lb-ft), Newton-meters (N·m), or other torque units.

- Quality Control: In beverage bottling, pharmaceutical, and food processing industries, maintaining consistent cap torque is essential to ensure product freshness, prevent leakage, and comply with quality standards. Torque testers help verify that bottle caps are tightened or sealed to the specified torque requirements.

- Seal Integrity: Proper cap torque is critical for ensuring the integrity of the seal between the bottle and the cap. In pharmaceuticals, for instance, a secure seal is necessary to maintain product sterility and safety. Torque testers help identify any issues with the sealing process.

- Calibration: Bottle cap torque testers are used to calibrate capping machines and ensure that they apply the correct torque during the sealing process. Regular calibration helps maintain the accuracy of capping equipment.

- Bottle Cap Design and Development: During the design and development of bottle caps, torque testers are used to evaluate cap performance, assess ease of opening, and optimize cap design for consumer convenience and safety.

- Data Logging and Documentation: Many modern bottle cap torque testers are equipped with data logging capabilities, allowing users to record torque measurements for documentation and quality assurance purposes. This data can be useful for tracking production trends and ensuring compliance with industry standards.

- Audible and Visual Feedback: Some torque testers provide audible and visual signals to indicate when the desired cap torque has been achieved, making it easier for operators to set and maintain the correct torque levels.

- Tolerance Testing: Bottle cap torque testers can perform tolerance testing to ensure that cap torque falls within specified tolerance limits, preventing issues like overtightening or undertightening.

- Safety: In industries where product safety is paramount, such as pharmaceuticals and food processing, bottle cap torque testers help ensure that bottles are sealed securely, minimizing the risk of contamination and ensuring consumer safety.

In summary, bottle cap torque testers play a crucial role in ensuring the quality, safety, and integrity of bottled products. They help maintain consistent cap torque, prevent sealing issues, and verify compliance with industry standards, ultimately contributing to efficient and reliable manufacturing processes.