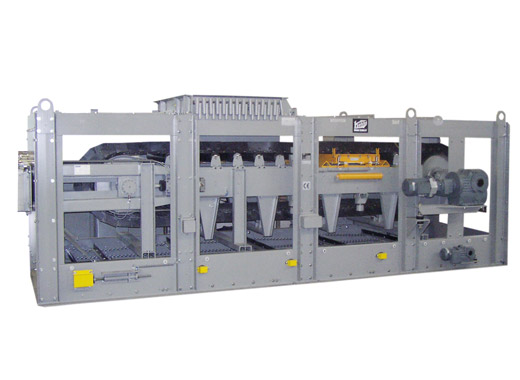

Usual rubber conveyor belts are not usable for bulk materials with very high temperatures. In these temperature ranges we use the KUKLA-apron weigh feeder. But even where large bunker cross sections for discharge of the material are necessary and where the wear and tear of a rubber conveyor belt is too high, KUKLA-apron weigh feeders can be used. In these scales the material is lying on robust metal plates. It was a great challenge for our engineers to integrate high-sensitive measuring technology.

Our engineers managed it in a way that is unique in the world. The typical range of application is in the cement-, magnesit- and steel industry in middle to high range conveying capacity for continuous dosing of grained bulk materials. An integrated, pneumatic belt steering device ensures high reliability.

Significant Benefits

- Test weight for an easy and quick check of the weighing accuracy

- Integrated belt steering device

- Minimal maintenance works

- For high temperatures

Requirement

- Stable vibration-free subconstruction

Conveying material: Bulk materials

Conveying capacity: 0,1 t/h – 1000 t/h

Belt speed: depending on the set point and the belt load

Belt width: 300 mm – 2000 mm

Bulk density: 500 kg/m³ – 4000 kg/m³

Granulation: fine grained to coarse-grained

Inclination conveyor belt: horizontal

Adjustment range: 1:10 (upgradeable up to 1:50 with feedback-encoder)

Accuracy: ± 0,5 – 2,0 %

No photo is available for this product

No video is available for this product