The AT2T ADATMV-ECO torque tester is an advanced, eco-friendly solution designed for precise torque measurement across a wide range of industries, including beverages, cosmetics, chemicals, food, and electrical products. This advanced torque tester is designed to meet the rigorous demands of modern manufacturing environments by offering high precision, reliability, and sustainability. Torque tester equipped with a high-speed microprocessor and precision stepper motor, it ensures exceptional accuracy and repeatability. Its semi-automatic operation makes torque tester easy to use while maintaining high performance. Compliant with FDA CFR 21-11, the ADATMV-ECO torque tester meets stringent regulatory requirements, making torque tester ideal for quality control and testing in various manufacturing environments. Its durable design and sustainable technology offer a reliable, cost-effective solution for torque testing. This increases operational efficiency while reducing the potential for human error. The torque tester is easy to use, requiring minimal training, yet delivers high performance that meets industry standards.

Technical specifications:

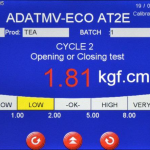

- Using by touch screen display

- Measures in opening and closing directions

- Measuring range: 00.00 to 99.00 Kgf.cm

- 3 measuring cycles (constant reading, Opening or Closing, Removal +Breaking)

- Units: Kgf.cm / N.m / Inch.lbs / N.cm

- Rotating speed adjustable

- Accuracy: 0.5 % of full scale

- 30 products memorization

- 10 thresholds (limits) option

- 10 operators memorization

- Configuration by protected password (administrator)

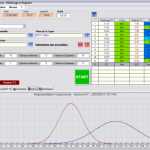

- Memorization up to 990 measures (transferable)

- Dynamic display: statistics / hour / date

- Display: product name / operator / batch N° / Sample N°

- 1 USB output and 1 printer output (software & printer)

- Language: English

- Delivered with calibration certificate COFRAC

- 110 / 230 V – 50/60 Hz

Automated part:

- Automatic zero before restarting cycle

- Settable height of column for all samples

- Easy-fast selector for cycles

- Settable speed for screwing and unscrewing operations

Mechanical specifications:

- Stainless steel Frame

- Choice of jaw, or bottle neck clamp

- Dimensions: 350 x 590 x 950 mm

- Weight: 50 kg

- Pneumatic chuck version

- Mini printer

- QUALITORQ Software

- Calibration pack

- Dynamometric system

- Choice of unit: Kgf.cm / Inch.lbs / N.cm / Nm.

- Adjustable rotation speed.

- Test chart.

- Accuracy 0.5% PE.

- 30 memorized products.

- Option of up to 8 thresholds (limits) (depending on the cycle).

- 10 memorized operators.

- Password protected configuration (administrator).

- Operating pressure monitoring, automatic warning for insufficient operating pressure.

- Memorization of 999 measurements.

- Dynamic display: statistics / time / date.

- Display: product name / operator / batch number / sample number.

- 1 RS232 & 1 mini-printer interface.

- English language.

- Delivered with COFRAC calibration certificate.

- Air network of 5 – 8 bars.

- AC 110 – 240 V 50/60 Hz.

- INOX set.

- Choice of jaw type (body or under bottle neck).

- Dimensions: 300x600x1050mm.

- Weight: 56 kg

• Mini printer

• QUALITORQ Software

• Calibration pack

• Dynamometric system