AT2E innovative HWBC-2 Hot Wire Bottle Cutter offers an automated and cost saving way for cutting containers for section weight analysis. A clean section without deformation will be obtained by a quick cutting of bottles through heated hot wires. A precision and repeatable cutting task is easy to achieve and it’s necessary for a proper analysis. With HWBC-2, an automatic and steady cutting process will be carried out after pressing the button. With exhaust fan and safety door design, the exhaust gas will be away from the operator during cutting. With HWBC-2, a PET bottle could be cut up to 5 predetermined sections under a steady force and excellent section plane could be obtained. Each section will be checked to ensure that it conforms to the exact weight assigned.

Features:

- Automatic and accurate cutting process offers a very easy way of operation

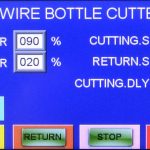

- Heating power / Standby power / Cutting speed / Return speed of wire / Cutting delay are adjustable

- Universal finish support, compatible for the bottle finish diameters from 17 to 40 mm

- Energy saving design

- Durable stainless steel design

- Touching screen offers easy and user-friendly operation

- Up to 5 sections cut and suitable for up to 2 L bottle

- Safety door and exhaust fan design which exhausts gases away from the operator

- Excellent repeatability

- Adjustable supports for bottles during the cutting process

- Graduated rulers allow accurate positioning of wires

- Sample range: Maximum height 360 mm

- Maximum diameter 110 mm

- Mains supply: 220 VAC / 50 Hz

- Overall size: 500 (L) x 580 (W) x 600 (H) mm

- Net weight: 48 KG