07-09-2023

A can seam check, also known as a can seam inspection or can seam examination, is a quality control process specifically designed for checking the integrity of the seam on a metal can, such as a tin can or aluminum can. The seam of a can is the area where the body of the can is joined and sealed with the lid or end. Ensuring the proper formation and sealing of this seam is crucial in various industries, particularly in food and beverage packaging, to prevent issues like leaks, spoilage, and contamination.

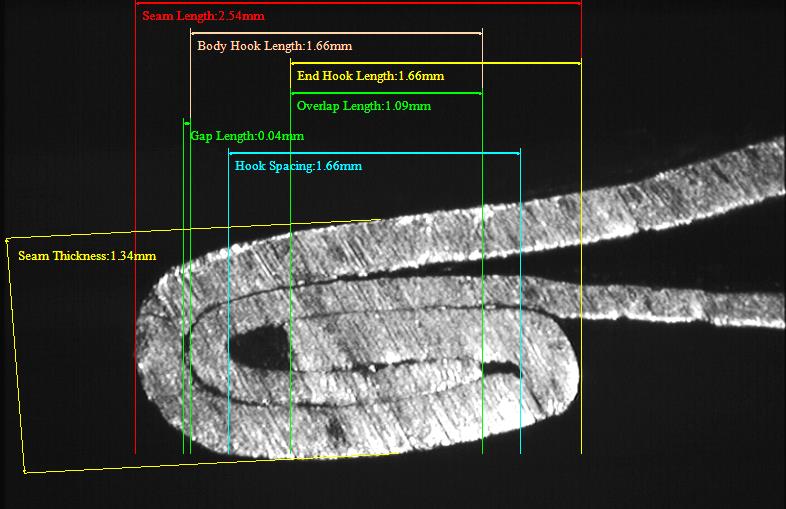

A can seam check involves a series of tests and inspections to assess the quality of the seam. Here are some of the key aspects typically examined during a can seam check:

Can seam checks are performed using specialized equipment and machines designed for this purpose. These machines may use various testing methods, such as mechanical measurements, visual inspection, and sometimes even pressure testing, to evaluate the quality of the seam.

The results of can seam checks are critical for ensuring the safety and quality of canned products. If a can seam is improperly sealed or compromised in any way, it can lead to issues such as product spoilage, contamination, or even safety hazards if the contents are under pressure.

Regular can seam checks are an integral part of quality control in can manufacturing and food and beverage production. They help maintain the consistency and reliability of canned products, ensuring that they meet the required standards and regulatory requirements.

Techotrix is providing the AT2E Seam Check Plus for monitoring the measurements above seam parameter.